Recyclable Polyolefin Impact Modifiers Market Set to Reach USD 3.1 Billion by 2036 | FMI Report

Recyclable polyolefin impact modifiers market gains momentum as sustainability mandates and rising packaging and automotive demand reshape material innovation.

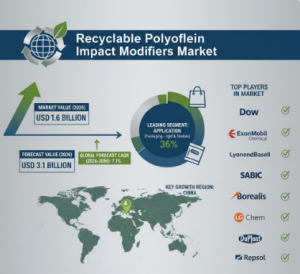

NEWARK, DE, UNITED STATES, January 27, 2026 /EINPresswire.com/ -- The global recyclable polyolefin impact modifiers market is projected to grow from approximately USD 1.6 billion in 2026 to nearly USD 3.1 billion by 2036, expanding at a compound annual growth rate (CAGR) of about 7.1% during the forecast period. This strong growth trajectory reflects rising global demand for high-performance plastic materials that enhance impact resistance while remaining fully compatible with recycling systems, particularly across packaging, automotive, construction, and consumer goods industries.

Recyclable polyolefin impact modifiers are increasingly being adopted to improve the toughness and durability of polyethylene and polypropylene without disrupting mono-material recycling streams. As sustainability goals tighten worldwide, manufacturers are prioritizing materials that meet both mechanical performance standards and circular economy requirements, positioning recyclable impact modifiers as a critical enabler of next-generation plastic solutions.

Key Market Insights at a Glance

Sustainability-driven material innovation remains the primary growth engine for the market. Packaging applications account for the largest consumption share as brand owners accelerate the transition toward recyclable and lightweight packaging formats. Automotive and construction sectors continue to integrate recyclable modifiers to meet durability requirements while aligning with regulatory mandates on emissions reduction and material recyclability. Rising investments in recycling infrastructure and polymer modification technologies further reinforce market expansion.

Segment Overview

By application, packaging—spanning rigid containers, films, and flexible solutions—represents nearly 36% of total market demand, supported by strong adoption in food, beverage, and personal care products. Automotive interiors and exterior components follow closely, where enhanced impact strength and recyclability are increasingly specified by OEMs. In terms of product type, polyolefin elastomers and plastomers dominate with roughly 34% share, favored for their superior flexibility, compatibility, and performance balance in recyclable polyolefin systems.

Regional Overview

Asia Pacific stands out as the fastest-growing regional market, supported by expanding manufacturing capacity, strong demand from packaging and automotive sectors, and increasing sustainability regulations. China remains a central growth contributor due to large-scale polymer production and rapid adoption of recyclable plastic technologies. North America and Europe continue to demonstrate steady growth, driven by stringent environmental regulations, corporate ESG commitments, and the growing adoption of circular material frameworks across industries.

Competitive Landscape

The market is moderately consolidated, with leading global chemical and polymer additive companies focusing on product innovation, sustainability-oriented portfolios, and strategic collaborations. Competitive differentiation increasingly centers on the ability to deliver high-impact performance modifiers that preserve recyclability while meeting evolving regulatory and customer requirements.

Market Outlook: Powering the Next Decade

Over the next decade, the recyclable polyolefin impact modifiers market is expected to play a pivotal role in advancing circular plastics. Growing mandates for recycled content, heightened consumer awareness, and increasing pressure on brands to reduce plastic waste will continue to drive adoption. Technological advancements in mechanical and chemical recycling are expected to improve recycled resin quality, further increasing demand for impact modifiers that maintain performance consistency in recycled polyolefin applications.

Key Players of Sustainable Polymer Additives

Key players operating in the market include Dow, BASF, Arkema, Borealis, SABIC, ExxonMobil Chemical, Mitsui Chemicals, LG Chem, LyondellBasell, and Mitsubishi Chemical Group, among others. These companies are actively strengthening their sustainable additive portfolios to address rising global demand for recyclable and high-performance polymer solutions.

Recent Strategic Developments

Recent industry developments include expanded production capacities, the launch of recyclable-compatible modifier grades, and strategic partnerships with packaging converters and automotive suppliers. Companies are also investing in R&D to design additives tailored for mono-material packaging and high-recycled-content applications, reinforcing long-term market competitiveness.

As sustainability and performance converge, recyclable polyolefin impact modifiers are set to become a cornerstone material solution, enabling industries worldwide to achieve durability, efficiency, and circularity goals simultaneously.

Request for Sample Report | Customize Report |purchase Full Report – https://www.futuremarketinsights.com/reports/sample/rep-gb-30246

Explore More Related Studies Published by FMI Research:

Phosphate Conversion Coatings Market https://www.futuremarketinsights.com/reports/phosphate-conversion-coatings-market

Industrial Pipe Insulation Market https://www.futuremarketinsights.com/reports/industrial-pipe-insulation-materials-market

Cinnamic Aldehyde Market https://www.futuremarketinsights.com/reports/cinnamic-aldehyde-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why Choose FMI: https://www.futuremarketinsights.com/why-fmi

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

rahul.singh@futuremarketinsights.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.